Oils and fats (100%)

Vegetable oils, recycled greases, animal fats, and future options from algae, bacteria, and fungi, cannot be used as such in conventional high-speed diesel engines. However, these can be converted into diesel compatible fuels with esterification (Fatty Acid Esters) or hydrotreatment processes (Paraffins). Oils and fats as such can be used in modified high-speed engines or in medium-duty diesel engines. In agriculture, there are engines manufactured for operation with "natural pure plant oil". In addition, existing diesel engines can be converted for vegetable oils by modifications into fuel lines, injectors, combustion chambers etc. However, in many regions clean fuels are required also for agricultural engines to meet stringent exhaust emission limits. (Agriforenergy 2011, Barnwal and Sharma 2005). Wood -based tall oil fatty acids are different from oils and fats, since they contain free acids that are aggressive towards materials. Therefore, unlike oils and fats, they cannot be used as such in internal combustion engines.

Vegetable oils and animal fats are triglycerides consisting of three fatty acids combined with glycerol. There are substantial differences in fatty acid compositions of oils and fats (Table 1). Chemical structure and fatty acid composition of oils and fats are discussed also in Fatty Acid Esters. Natural oils and fats contain impurities, for example, free fatty acids, phospholipids, sterols, water, and odorants. Purification and processing methods developed for vegetable oils may not be directly applicable for animal fats (Fangrui and Milford 1999).

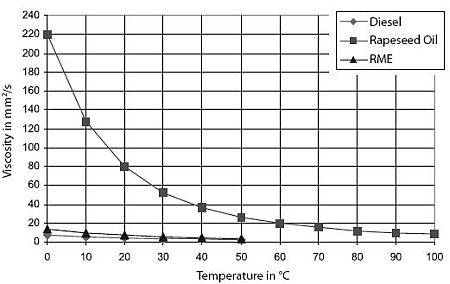

Viscosity is the most substantial difference between vegetable oils and diesel fuel. Viscosity of rapeseed oil is more than ten-fold when compared to diesel fuel. Rapeseed oil needs to be heated up to some 90 °C, before its viscosity is close to that of diesel fuel (Figure 1). Some vegetable oils with a high portion of saturated fatty acids, such as palm oil and beef tallow, are solid at room temperature. High viscosity of vegetable oils can result in various problems in conventional diesel engines, for example poor durability of the fuel injection system, improper spray formation, engine deposits and high exhaust emissions. Cetane numbers of vegetable oils are low, in a range of 32-40.

Figure 1. The effect of temperature on viscosity of rape seed oil, RME, and diesel fuel.

Table 1. Selected properties of vegetable oils and animal fats.

|

|

Rapeseeda,e,f |

Sunflowera,e |

Camelinaa |

Palm oilb,e |

Soybeanb,e |

Olivee |

Chicken fatb |

Beef tallowb,ce |

|

14:0 Myristic acid * |

- |

- |

- |

0.6 – 2.4 |

- |

1.3 |

1 |

3 – 6 |

|

16:0 Palmitic acid |

3.2 - 5.0 |

3.5 – 6.5 |

5.1 |

32 – 46.3 |

2.3 – 11 |

7 – 18.3 |

25 |

25 – 37 |

|

16:1 Palmitoleic acid |

|

|

|

|

|

|

8 |

4 |

|

18:0 Stearic acid |

1.0 – 2.5 |

1.3 – 5.6 |

2.2 |

4 – 6.3 |

2.4 – 6 |

1.4 – 3.3 |

6 |

14 – 29 |

|

18:1 Oleic acid |

52.6 - 64a,e,f |

14 – 43 |

14.0 |

37 – 53 |

22 – 30.8 |

55.5 – 84.5 |

41 |

26 – 50 |

|

18:2 Linoleic acid |

20 - 28.1 |

44 – 68.7 |

17.4 |

6 – 12 |

49 – 54 |

4 – 19 |

18 |

1 – 3 |

|

18:3 Linolenic acid |

9 - 15.5 |

- |

40.1 |

|

2 – 10.5 |

|

1 |

|

|

20:0 Arahidic acid |

- |

4 |

1.3 |

|

|

|

|

|

|

20:1 Eicosatrienic acid |

- |

- |

13.4 |

|

|

|

|

|

|

22:1 Erucic acid |

0.0 – 1.7 ** |

- |

3.1 |

|

|

|

|

|

|

Other |

- |

2.3 |

3.4 |

|

|

|

|

15 |

|

|

|

|

|

|

|

|

|

|

|

Kinematic viscosity at 38 °C, mm2/s |

37.0d |

33.9d |

|

39.6d |

32.6d |

|

|

|

|

Cetane number |

37.6d 37.6 – 44d,e,f |

37.1d,e 33f |

|

42.0d

|

37.9d

|

|

|

|

|

Heating value, MJ/kg |

39.7d |

39.6d |

|

- |

39.6d |

|

|

40.1 |

|

Cloud point, °C |

-4 – -15 |

7.2d |

|

31.0d, f |

-3.9d |

|

|

|

|

Pour point, °C |

-20 – -32 |

-15.0d |

|

- |

-12.2d |

|

|

|

|

Flash point, °C |

246d >150e, f |

274d 323f |

|

267d |

254d 320f |

|

|

|

|

Density, kg/dm3 |

0.9115d |

0.9161d |

|

0.9180d, f |

0.9138d |

|

|

|

|

Density 15 °C (kg/m3) |

910 – 950 |

924f |

|

|

923f |

|

|

|

|

Acid value, mg KOH/g |

1.14c |

0.15c |

|

|

0.2c |

|

|

|

|

Iodine number, g/100 g |

94 – 120 |

110 – 143 |

160 |

35 – 61 |

117 – 143 |

75 – 94 |

|

35 – 48c |

|

Wiley melting point |

|

|

|

|

|

|

|

47 – 50c |

|

Viscosity 38-40 °C (mm2/s) |

37.0 |

37.1 |

|

40f |

32.6 |

|

|

51.15 |

|

Distillation IBP (°C) FBP (°C) |

215 246 – 340 |

274 |

|

|

254 |

|

|

201 |

|

Lower heating value (MJ/kg) |

37 |

|

|

|

|

|

|

|

|

Ash (wt-%) |

<0.01 |

|

|

|

|

|

|

|

|

Carbon residue (wt-%) |

<0.25 |

0.4f |

|

|

|

|

|

|

* First number indicates fatty acid chain length and the second one indicates number of double bonds. ** Eerucic acid content of rapeseed oil depends on seeds aAgriforfuel 2011 bMoser 2009 cMa and Hanna 1999 dBarnwal and Sharma 2005 eKnothe 1997 f Various references collected in 1994 (Aakko)

References

Agriforenergy (2011) Pure Plant Oil as Fuel - Technical aspects and legislative context. (www.agriforenergy.com)

Barnwal, B.K. and Sharma, M.P. (2005) Prospects of biodiesel production from vegetable oils in India. Renewable and Sustainable Energy Reviews, 9 (2005) 363-378.

Fangrui, M. and Milford, A. H. (1999) Biodiesel production: a review.

Knothe, G., Dunn, R.O. & Bagby, M.O. 1997. Biodiesel: The use of vegetable oils and their derviatives as alternative diesel fuels. In Fuels and Chemicals from Biomass, National Center for Agricultural Utilization Research, U.S. Department of Agriculture, USA.

Moser, B. (2009) Biodiesel production, properties, and feedstocks. In vitro Cell.Dev.Biol. -Plant (2009) 45:229-266